What's your challenge?

DM's AM2.Production Team can help solve it

Every manufacturer has challenges. Whether it's getting new products to market faster on budget, delivering on tougher new performance requirements, improving your sustainability footprint, or delivering on once-impossible advancements.

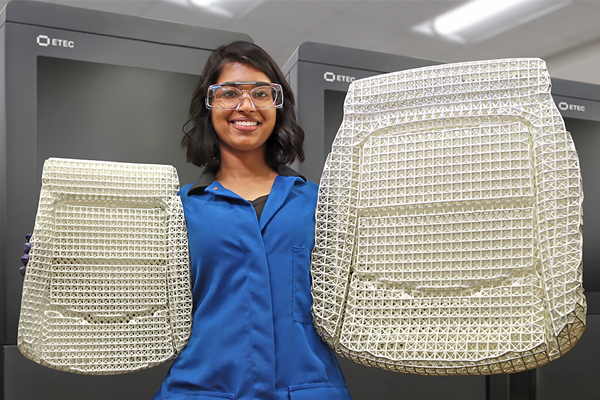

Desktop Metal's AM2.Pro team can help you solve it. We're home to the world's leading team of additive manufacturing experts in metals, ceramics and polymers, including elastomers and foams.

Our team has been successfully helping solve complex challenges for global companies for decades now. That includes automakers, medical device, industrial and consumer goods companies, as well as government and defense agencies.

Solutions for complex problems

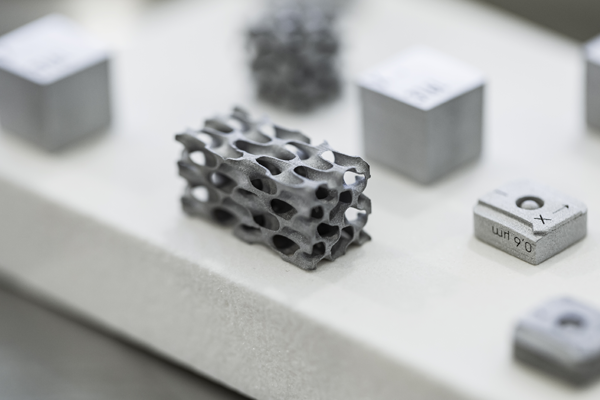

Our binder jet (BJT) 3D printing and digital light processing (DLP) platforms are highly flexible and have already proven themselves capable at solving complex problems for other customers.

Our AM2.Production Pros

Team DM is comprised of some of the brightest engineering minds in the world. Learn more about our team of additive manufacturing experts.

Metal and Ceramic Leadership

Rick Lucas

Senior VP Future Markets

MBA and over two decades of leading industry-focused research teams

Leads our team of experts in pushing the boundaries of binder jetting technology to expand the materials and applications available.

Meet our Metal Experts

Patrick Dougherty, PhD

Director of Commercial R&D

PhD in Mechanical Engineering

Brings powder mechanics experience from a variety of industrial fields to fill in the gaps between material, machine, and process to make binder jetting fit for any application.

Kyle Myers, PhD

Director of Process and Materials

PhD in Materials Science and Engineering

Works to advance the development of next-generation binder jetting materials such as copper and tungsten for advancing the production options of metal 3D printing applications.

Mihaela Nastac

Senior Metallurgical Engineer

MS in Metallurgy and 15 years with the company after starting her career as a foundry plant engineer

Brings a scientific-based approach for sandcasting rigging design with a mix of metallurgy, chemistry, and physics to advance first-pour success with digital casting technology.

Meet our Ceramics Experts

Benjamin Groth, PhD

Research Scientist

PhD in Materials Engineering

Uses a background of research in ceramic materials to help customers focused on 3D printing technical ceramics transfer their application to binder jetting.

Partnership Process

Our low-risk production adoption process helps to ensure your success. We help you determine if our technology is right for your application — from both a technical and business perspective — and we partner with you for the whole journey.

DM's AM2.Pro Team can help you, too.

While every challenge is different, our trusted process has led to success for many customers. Our process includes:

- A complete discovery and intake of your challenge

- An analysis of your requirements for design and geometry, material properties, accuracy and functional performance.

- A detailed discussion of your business challenges, such as time to market, supply chain constraints, and part cost requirements

- A comprehensive executive report on the technical and business case to proceed with an Additive Manufacturing 2.0 solution from Desktop Metal, customized to your needs.

We will collaborate with you to determine if one of our technologies can deliver a solution for your needs.